I. Brief Introduction

Yokogawa ProSafe-RS safety instrumented system (SIS), which plays a crucial role in ensuring plant safetyand draws from supremely reliable distributed control system (DCS) technology and strong track record in the DCS and SIS businesses. Before ProSafe-RS, DCSs and SISs were typically supplied by different vendors and required extra engineering for the individual systems and interconnections. Furthermore, these systems were more difficult to master and operate as they had different interfaces. ProSafe-RS overcomes these hurdles through complete integration with Yokogawa’s CENTUM DCS – an industry first. The ProSafe-RS has been a global success since its debut in 2005, and is continually being improved.

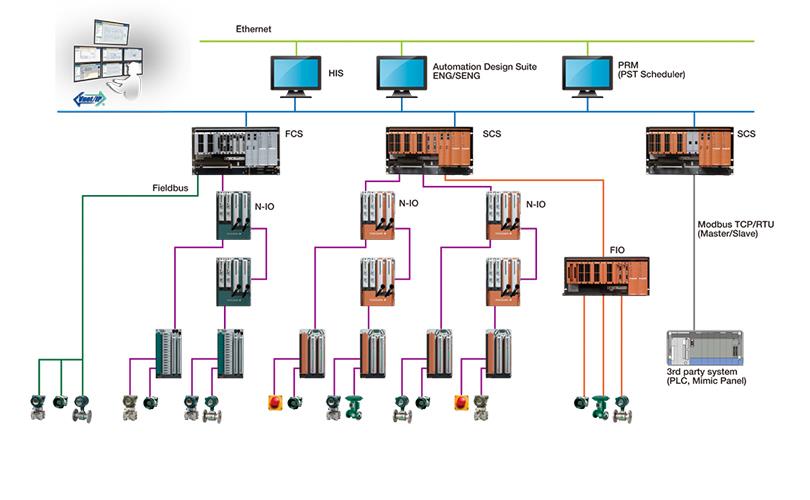

With its advanced diagnostics and dual redundant architecture in every module, ProSafe-RS achieves a high safety integrity level (SIL3) and is highly reliable. All of the communication paths within the modules as well as links to other modules and systems are dual redundant as well. The unique architecture of this Yokogawa system ensures maximum safety and reliability; A high-speed CPU with a large memory ensures suf¬cient process safety time, even with large systems. With its outstanding scalability and suitability for widely distributed applications, this system offers both exibility and unsurpassed performance, whatever the con-guration. Through its tight integration with control systems and asset management systems, the Yokogawa ProSafe-RS delivers Operational Excellence, Asset Excellence, and Safety Excellence to oil and gas upstream and downstream operations and to chemical, power, and steel plants; With a variety of tools and functions, Yokogawa offers assistance and support through all phases of the plant lifecycle, from engineering to operation and maintenance. And through our global network of safety engineers and of¬ces, we are well positioned to provide on-site support to our customers around the world.

It owns main technial features below:

1.1. SIL3 certified: Both single and redundent modules are SIL3 certified, IEC61508・61511; PFD ave < 10-3 x15%, CPU & IOM have internal duplex channel architecture with comparator and diagnostic functions.

1.2. High availability: Provides high availability reached by redundant module options of CPU module & I/O module, the proven redundant technology from CS3000.

1.3. Versatile Modular Redundancy: Low false Trip is realized by VMR based on proven “Pair & Spare” technology, even when an internal failure is diagnosed, safety functionality is kept. Internal failure in SIS does not affect the process, Moreover, on-line change of failure module is possible without affecting the process.

1.4. Safety Application: Complies to Safety related and high availability applications of Burner Management System (BMS), and Fire and Gas (F&G) System; such as EN 298, EN 50156-1, NFPA 85, EN 54-2, NFPA 72.

1.5. Scalbe configuration: 1 domain supports 64 stations, around 100,000 tags; 1 CPU node supports 100 I/Os, 1 CPU & Node supports 1000 I/Os.

1.6. Temperature Adaptability: for standard type is -20 to 40 ˚C , for Wide range temperature type is -20 to 70 ˚C.

1.7. SOE function: SENG Upload events to the SCS and save in the SCS via the Message cache service, and display them in the SOE Viewer, The SOE Viewer can be installed in HIS as an option, SCS Acquire and save the data from DI modules or logic in the buffer with 1msec resolution.

1.8. Input/Output Modules: Digital Input Module 24V, Digital Output Module 24V & 110V, Analog Input Module 24V, Analog Input Module 1-10V, Analog Output Module 4-20mA. It's flexible for any mix of single or dual redundant modules. Safety devices diagnostic by PRM, Collecting HART Device Information, HART signal goes through ProSafe-RS without any HART devices.

1.9. Line Monitoring Function: Detect disconnected or short-circuited field wiring between the digital input module and field equipment.

1.10. Remote I/O for Long Distance: It max. 50Km by Optic-fiber cable, No affects to scan time for max 9 nodes; Chain type & Star type connection.

1.11. Common HMI: one window HIS overview, Process Alarm, Graphics, Faceplate, SCS Status Display; Control and Monitoring SIS Safely from HIS.

1.12. Network: The one Unified Network which is Smart, Simple and Cost effective, supports Precise Time Synchronization.

1.13. Simulation: Integrated Operator Training System (OTS)” can be built with “CENTUM VP - ProSafe-RS Integrated test function” and “Exatif” (interface to a process simulator).

II. Integration & Engineering Service

2.1 System Engineering and Design

2.2 Hardware integration and software configuration

2.3 System assembly, integration test and FAT

2.4 Site conmmissioning

2.5 Traning

2.6 Maintenance service: Daily service, revamping service, Emergency service.