1. General introduction

Supreme Coriolis mass flow meter is for accurate flow applications, typical line sizes: DN15, DN25, DN40, DN50, DN65, DN80, DN100, DN125, 1/4”, 1/2”, 1”, 1 1/2”, 2”, 3”, 4”, 5”and maximum mass flow up to 170 t/h and volume up to 170 m3/h, delivers unsurpassed performance for demanding and critical applications with superior aeration handling and advanced diagnostic functionality.

2. Measuring range limits

Meter size | Normal Mass Flow | Maximum mass flow | Normal Volume flow | Max Volume flow | Normal Temperature | Max. Temperature | Density |

Supreme 34 | 3 t/h | 5 t/h | 3 m3/h | 5 m3/h | -50 to150℃ | -70 to 350℃ | 0 to 5 kg/l |

Supreme 36 | 10 t/h | 17 t/h | 10 m3/h | 17 m3/h | |||

Supreme 38 | 32 t/h | 50 t/h | 32 m3/h | 50 m3/h | 0 to 2 kg/l | ||

Supreme 39 | 100 t/h | 170 t/h | 100 m3/h | 170 m3/h |

3. Accuracy of liquids Measurement

Measured quantity | Accuracy for transmitters | ||

Essential | Ultimate | ||

Mass flow | Accuracy | 0.15 % of measured value | 0.1 % of measured value |

Repeatability | 0.08 % of measured value | 0.05 % of measured value | |

Volume flow | Accuracy | 0.43 % of measured value | 0.12 % of measured value |

Repeatability | 0.22 % of measured value | 0.06 % of measured value | |

Density | Accuracy | 4 g/l (0.25 lb/ft³) | 0.5 g/l (0.03 lb/ft³) |

Repeatability | 2 g/l (0.13 lb/ft³) | 0.3 g/l (0.02 lb/ft³) | |

Temperature | Accuracy | 0.5℃ (0.9℉) | 0.5℃ (0.9℉) |

4. Accuracy of gas Measurement

Measured quantity | Accuracy for transmitters | ||

Essential | Ultimate | ||

Mass flow | Accuracy | 0.75 % of measured value | 0.5 % of measured value |

Repeatability | 0.6 % of measured value | 0.4 % of measured value | |

Volume flow | Accuracy | 0.75 % of measured value | 0.5 % of measured value |

Repeatability | 0.6 % of measured value | 0.4 % of measured value | |

Temperature | Accuracy | 0.5℃ (0.9℉) | 0.5℃ (0.9℉) |

5. Model selection of Supreme 34

Main Code | Suffix Codes | Description | |||||||||||||

RC | Always RC | ||||||||||||||

Transmitter | E | Essential (base function) | |||||||||||||

U | Ultimate (high function) | ||||||||||||||

Sensor | S | Supreme | |||||||||||||

Meter size | 34 | Nominal mass flow : 3 t/h (110 lb/min), Maximum mass flow: 5 t/h (180 lb/min) | |||||||||||||

Material of wetted parts | S | Stainless steel 1.4404/316L | |||||||||||||

H | Ni alloy C-22/2.4602 | ||||||||||||||

Process connection size | 08 | ⅜" | |||||||||||||

15 | DN15, ½" | ||||||||||||||

20 | ¾" | ||||||||||||||

25 | DN25, 1" | ||||||||||||||

40 | DN40, 1½" | ||||||||||||||

50 | 2" | ||||||||||||||

Process connection type | BA1 | ASME flange class 150, suitable for ASME B16.5, raised face (RF) | |||||||||||||

BA2 | ASME flange class 300, suitable for ASME B16.5, raised face (RF) | ||||||||||||||

BA4 | ASME flange class 600, suitable for ASME B16.5, raised face (RF) | ||||||||||||||

CA4 | ASME flange class 600, suitable for ASME B16.5, ring joint (RJ) | ||||||||||||||

BD4 | EN flange PN 40, suitable for EN 1092-1 type B1, raised face (RF) | ||||||||||||||

ED4 | EN flange PN 40, suitable for EN 1092-1 type E, spigot | ||||||||||||||

FD4 | EN flange PN 40, suitable for EN 1092-1 type F, recess | ||||||||||||||

GD4 | EN flange PN 40, suitable for EN 1092-1 type D, groove | ||||||||||||||

BD6 | EN flange PN 100, suitable for EN 1092-1 type B1, raised face (RF) | ||||||||||||||

ED6 | EN flange PN 100, suitable for EN 1092-1 type E, spigot | ||||||||||||||

FD6 | EN flange PN 100, suitable for EN 1092-1 type F, recess | ||||||||||||||

GD6 | EN flange PN 100, suitable for EN 1092-1 type D, groove | ||||||||||||||

BJ1 | JIS flange 10K, JIS B 2220 | ||||||||||||||

BJ2 | JIS flange 20K, JIS B 2220 | ||||||||||||||

BP1 | JPI flange class 150 | ||||||||||||||

BP2 | JPI flange class 300 | ||||||||||||||

BP4 | JPI flange class 600 | ||||||||||||||

TG9 | Process connection with internal thread G | ||||||||||||||

TT9 | Process connection with internal thread NPT | ||||||||||||||

HS4 | Clamp process connection according to DIN 32676 series A | ||||||||||||||

HS8 | Clamp process connection according to DIN 32676 series C (Tri-Clamp) | ||||||||||||||

HS9 | Clamp process connection according to JIS/ISO 2852 | ||||||||||||||

Sensor housing 0material | 0 | Stainless steel 1.4301/304, 1.4404/316L | |||||||||||||

1 | Stainless steel 1.4404/316L | ||||||||||||||

Process fluid temperature range | 0 | Standard integrate: -50 to 150℃ (-58 to 302℉), remote type: -70 to 200 °C (-94 – 392 °F) | |||||||||||||

2 | Mid-range: -70 to 230℃ (-94 to 446℉) | ||||||||||||||

3 | High: 0 to 350℃ (32 to 662℉) | ||||||||||||||

Mass flow and density accuracy | E7 | Liquid: 0.2 % maximum mass flow deviation, 4 g/l density deviation | |||||||||||||

D7 | Liquid: 0.15 % maximum mass flow deviation, 4 g/l density deviation | ||||||||||||||

C6 | Liquid: 0.1 % maximum mass flow deviation, 3 g/l density deviation | ||||||||||||||

C3 | Liquid: 0.1 % maximum mass flow deviation, 1 g/l density deviation | ||||||||||||||

C2 | Liquid: 0.1 % maximum mass flow deviation, 0.5 g/l density deviation | ||||||||||||||

70 | Gas: 0.75% maximum mass flow deviation | ||||||||||||||

50 | Gas: 0.5% maximum mass flow deviation | ||||||||||||||

Design and housing | 0 | Integral type with "urethane-cured polyester powder coating" coated aluminum transmitter housing | |||||||||||||

2 | Integral type with "corrosion protection coating" coated aluminum transmitter housing | ||||||||||||||

A | Remote type with "urethane-cured polyester powder coating" coated aluminum transmitter housing and standard neck sensor | ||||||||||||||

B | Remote type with "urethane-cured polyester powder coating" coated aluminum transmitter housing and long neck sensor | ||||||||||||||

E | Remote type with "corrosion protection coating" coated aluminum transmitter housing and standard neck sensor | ||||||||||||||

F | Remote type with "corrosion protection coating" coated aluminum transmitter housing and long neck sensor | ||||||||||||||

J | Remote type stainless steel transmitter and standard neck sensor | ||||||||||||||

K | Remote type stainless steel transmitter and long neck sensor | ||||||||||||||

Ex approval | NN00 | None | |||||||||||||

KF21 | ATEX, explosion group IIC and IIIC | ||||||||||||||

KF22 | ATEX, explosion group IIB and IIIC | ||||||||||||||

SF21 | IECEx, explosion group IIC and IIIC | ||||||||||||||

SF22 | IECEx, explosion group IIB and IIIC | ||||||||||||||

GF21 | EAC Ex, explosion group IIC and IIIC | ||||||||||||||

GF22 | EAC Ex, explosion group IIB and IIIC | ||||||||||||||

FF11 | FM, groups A, B, C, D, E, F, G | ||||||||||||||

FF12 | FM, groups C, D, E, F, G | ||||||||||||||

UF21 | INMETRO, explosion group IIC and IIIC | ||||||||||||||

UF22 | INMETRO, explosion group IIB and IIIC | ||||||||||||||

NF21 | NEPSI, explosion group IIC and IIIC | ||||||||||||||

NF22 | NEPSI, explosion group IIB and IIIC | ||||||||||||||

PF21 | Korea Ex, explosion group IIC and IIIC | ||||||||||||||

PF22 | Korea Ex, explosion group IIB and IIIC | ||||||||||||||

Cable entries | 2 | ANSI ½" NPT | |||||||||||||

4 | ISO M20x1.5 | ||||||||||||||

Communication type and I/O | JA | active current output HART,1 passive pulse or status output | |||||||||||||

JB | 2 active current outputs one with HART,2 passive pulse or status outputs | ||||||||||||||

JC | 2 active current outputs one with HART,1 passive pulse or status output,1 voltage-free status input | ||||||||||||||

JD | 1 active current output HART,2 passive pulse or status outputs,1 passive status output | ||||||||||||||

JE | 1 active current output HART,2 passive pulse or status outputs,1 voltage-free status input | ||||||||||||||

JF | 1 active current output HART,1 passive pulse or status output,1 active pulse or status output with pull-up resistor,1 voltage-free status input | ||||||||||||||

JG | 1 active current output HART,1 passive pulse or status output,1 active pulse or status output,1 voltage-free status input | ||||||||||||||

JH | 1 active current output HART,1 passive pulse or status output,1 passive current output,1 active current input | ||||||||||||||

JJ | 1 active current output HART,2 passive pulse or status outputs,1 active current input | ||||||||||||||

JK | 1 active current output HART,1 passive pulse or status output,1 voltage-free status input,1 active current input | ||||||||||||||

JL | 1 active current output HART,1 passive pulse or status output,1 passive current output,1 passive current input | ||||||||||||||

JM | 1 active current output HART, 2 passive pulse or status outputs,1 passive current input | ||||||||||||||

JN | 1 active current output HART,1 passive pulse or status output,1 voltage-free status input,1 passive current input | ||||||||||||||

JP | 2 passive current outputs one with HART,1 passive pulse or status output | ||||||||||||||

JQ | 2 passive current outputs one with HART,2 passive pulse or status outputs | ||||||||||||||

JR | 2 passive current outputs one with HART,1 passive NAMUR pulse or status output | ||||||||||||||

JS | 2 passive current outputs one with HART,2 passive NAMUR pulse or status outputs | ||||||||||||||

M0 | Modbus output,1 passive pulse or status output | ||||||||||||||

M2 | Modbus output,1 passive pulse or status output,1 active current input | ||||||||||||||

M3 | Modbus output, 2 passive pulse or status outputs | ||||||||||||||

M4 | Modbus output,1 passive pulse or status output, 1 active pulse or status output | ||||||||||||||

M5 | Modbus output, 1 passive pulse or status output, 1 active pulse or status output with pull-up resistor | ||||||||||||||

M6 | Modbus output,1 passive pulse or status output, 1 active current output | ||||||||||||||

M7 | Modbus output, 1 passive pulse or status output, 1 passive current input | ||||||||||||||

Display | 0 | No display | |||||||||||||

1 | With display | ||||||||||||||

Optional codes | /Optional codes | ||||||||||||||

6. Model selection of Supreme 36

Main Code | Suffix Codes | Description | |||||||||||||

RC | Always RC | ||||||||||||||

Transmitter | E | Essential (base function) | |||||||||||||

U | Ultimate (high function) | ||||||||||||||

Sensor | S | Supreme | |||||||||||||

Meter size | 36 | Nominal mass flow : 10 t/h (370 lb/min), Maximum mass flow: 17 t/h (620 lb/min) | |||||||||||||

Material of wetted parts | S | Stainless steel 1.4404/316L | |||||||||||||

H | Ni alloy C-22/2.4602 | ||||||||||||||

Process connection size | 25 | DN25, 1" | |||||||||||||

40 | DN40, 1½" | ||||||||||||||

50 | 2" | ||||||||||||||

Process connection type | BA1 | ASME flange class 150, suitable for ASME B16.5, raised face (RF) | |||||||||||||

BA2 | ASME flange class 300, suitable for ASME B16.5, raised face (RF) | ||||||||||||||

BA4 | ASME flange class 600, suitable for ASME B16.5, raised face (RF) | ||||||||||||||

CA4 | ASME flange class 600, suitable for ASME B16.5, ring joint (RJ) | ||||||||||||||

BD4 | EN flange PN 40, suitable for EN 1092-1 type B1, raised face (RF) | ||||||||||||||

ED4 | EN flange PN 40, suitable for EN 1092-1 type E, spigot | ||||||||||||||

FD4 | EN flange PN 40, suitable for EN 1092-1 type F, recess | ||||||||||||||

GD4 | EN flange PN 40, suitable for EN 1092-1 type D, groove | ||||||||||||||

BD6 | EN flange PN 100, suitable for EN 1092-1 type B1, raised face (RF) | ||||||||||||||

ED6 | EN flange PN 100, suitable for EN 1092-1 type E, spigot | ||||||||||||||

FD6 | EN flange PN 100, suitable for EN 1092-1 type F, recess | ||||||||||||||

GD6 | EN flange PN 100, suitable for EN 1092-1 type D, groove | ||||||||||||||

BJ1 | JIS flange 10K, JIS B 2220 | ||||||||||||||

BJ2 | JIS flange 20K, JIS B 2220 | ||||||||||||||

BP1 | JPI flange class 150 | ||||||||||||||

BP2 | JPI flange class 300 | ||||||||||||||

BP4 | JPI flange class 600 | ||||||||||||||

TG9 | Process connection with internal thread G | ||||||||||||||

TT9 | Process connection with internal thread NPT | ||||||||||||||

HS4 | Clamp process connection according to DIN 32676 series A | ||||||||||||||

HS8 | Clamp process connection according to DIN 32676 series C (Tri-Clamp) | ||||||||||||||

HS9 | Clamp process connection according to JIS/ISO 2852 | ||||||||||||||

Sensor housing 0material | 0 | Stainless steel 1.4301/304, 1.4404/316L | |||||||||||||

1 | Stainless steel 1.4404/316L | ||||||||||||||

Process fluid temperature range | 0 | Standard integrate: -50 to 150℃ (-58 to 302℉), remote type: -70 to 200 °C (-94 – 392 °F) | |||||||||||||

2 | Mid-range: -70 to 230℃ (-94 to 446℉) | ||||||||||||||

3 | High: 0 to 350℃ (32 to 662℉) | ||||||||||||||

Mass flow and density accuracy | E7 | Liquid: 0.2 % maximum mass flow deviation, 4 g/l density deviation | |||||||||||||

D7 | Liquid: 0.15 % maximum mass flow deviation, 4 g/l density deviation | ||||||||||||||

C6 | Liquid: 0.1 % maximum mass flow deviation, 3 g/l density deviation | ||||||||||||||

C3 | Liquid: 0.1 % maximum mass flow deviation, 1 g/l density deviation | ||||||||||||||

C2 | Liquid: 0.1 % maximum mass flow deviation, 0.5 g/l density deviation | ||||||||||||||

70 | Gas: 0.75% maximum mass flow deviation | ||||||||||||||

50 | Gas: 0.5% maximum mass flow deviation | ||||||||||||||

Design and housing | 0 | Integral type with "urethane-cured polyester powder coating" coated aluminum transmitter housing | |||||||||||||

2 | Integral type with "corrosion protection coating" coated aluminum transmitter housing | ||||||||||||||

A | Remote type with "urethane-cured polyester powder coating" coated aluminum transmitter housing and standard neck sensor | ||||||||||||||

B | Remote type with "urethane-cured polyester powder coating" coated aluminum transmitter housing and long neck sensor | ||||||||||||||

E | Remote type with "corrosion protection coating" coated aluminum transmitter housing and standard neck sensor | ||||||||||||||

F | Remote type with "corrosion protection coating" coated aluminum transmitter housing and long neck sensor | ||||||||||||||

J | Remote type stainless steel transmitter and standard neck sensor | ||||||||||||||

K | Remote type stainless steel transmitter and long neck sensor | ||||||||||||||

Ex approval | NN00 | None | |||||||||||||

KF21 | ATEX, explosion group IIC and IIIC | ||||||||||||||

KF22 | ATEX, explosion group IIB and IIIC | ||||||||||||||

SF21 | IECEx, explosion group IIC and IIIC | ||||||||||||||

SF22 | IECEx, explosion group IIB and IIIC | ||||||||||||||

GF21 | EAC Ex, explosion group IIC and IIIC | ||||||||||||||

GF22 | EAC Ex, explosion group IIB and IIIC | ||||||||||||||

FF11 | FM, groups A, B, C, D, E, F, G | ||||||||||||||

FF12 | FM, groups C, D, E, F, G | ||||||||||||||

UF21 | INMETRO, explosion group IIC and IIIC | ||||||||||||||

UF22 | INMETRO, explosion group IIB and IIIC | ||||||||||||||

NF21 | NEPSI, explosion group IIC and IIIC | ||||||||||||||

NF22 | NEPSI, explosion group IIB and IIIC | ||||||||||||||

PF21 | Korea Ex, explosion group IIC and IIIC | ||||||||||||||

PF22 | Korea Ex, explosion group IIB and IIIC | ||||||||||||||

Cable entries | 2 | ANSI ½" NPT | |||||||||||||

4 | ISO M20x1.5 | ||||||||||||||

Communication type and I/O | JA | active current output HART,1 passive pulse or status output | |||||||||||||

JB | 2 active current outputs one with HART,2 passive pulse or status outputs | ||||||||||||||

JC | 2 active current outputs one with HART,1 passive pulse or status output,1 voltage-free status input | ||||||||||||||

JD | 1 active current output HART,2 passive pulse or status outputs,1 passive status output | ||||||||||||||

JE | 1 active current output HART,2 passive pulse or status outputs,1 voltage-free status input | ||||||||||||||

JF | 1 active current output HART,1 passive pulse or status output,1 active pulse or status output with pull-up resistor,1 voltage-free status input | ||||||||||||||

JG | 1 active current output HART,1 passive pulse or status output,1 active pulse or status output,1 voltage-free status input | ||||||||||||||

JH | 1 active current output HART,1 passive pulse or status output,1 passive current output,1 active current input | ||||||||||||||

JJ | 1 active current output HART,2 passive pulse or status outputs,1 active current input | ||||||||||||||

JK | 1 active current output HART,1 passive pulse or status output,1 voltage-free status input,1 active current input | ||||||||||||||

JL | 1 active current output HART,1 passive pulse or status output,1 passive current output,1 passive current input | ||||||||||||||

JM | 1 active current output HART, 2 passive pulse or status outputs,1 passive current input | ||||||||||||||

JN | 1 active current output HART,1 passive pulse or status output,1 voltage-free status input,1 passive current input | ||||||||||||||

JP | 2 passive current outputs one with HART,1 passive pulse or status output | ||||||||||||||

JQ | 2 passive current outputs one with HART,2 passive pulse or status outputs | ||||||||||||||

JR | 2 passive current outputs one with HART,1 passive NAMUR pulse or status output | ||||||||||||||

JS | 2 passive current outputs one with HART,2 passive NAMUR pulse or status outputs | ||||||||||||||

M0 | Modbus output,1 passive pulse or status output | ||||||||||||||

M2 | Modbus output,1 passive pulse or status output,1 active current input | ||||||||||||||

M3 | Modbus output, 2 passive pulse or status outputs | ||||||||||||||

M4 | Modbus output,1 passive pulse or status output, 1 active pulse or status output | ||||||||||||||

M5 | Modbus output, 1 passive pulse or status output, 1 active pulse or status output with pull-up resistor | ||||||||||||||

M6 | Modbus output,1 passive pulse or status output, 1 active current output | ||||||||||||||

M7 | Modbus output, 1 passive pulse or status output, 1 passive current input | ||||||||||||||

Display | 0 | No display | |||||||||||||

1 | With display | ||||||||||||||

Optional codes | /Optional codes | ||||||||||||||

7. Model selection of Supreme 38

Main Code | Suffix Codes | Description | |||||||||||||

RC | Always RC | ||||||||||||||

Transmitter | E | Essential (base function) | |||||||||||||

U | Ultimate (high function) | ||||||||||||||

Sensor | S | Supreme | |||||||||||||

Meter size | 38 | Nominal mass flow : 32 t/h (1200 lb/min), Maximum mass flow: 50 t/h (1800 lb/min) | |||||||||||||

Material of wetted parts | S | Stainless steel 1.4404/316L | |||||||||||||

H | Ni alloy C-22/2.4602 | ||||||||||||||

Process connection size | 40 | DN40, 1½" | |||||||||||||

50 | 2" | ||||||||||||||

65 | DN65, 2½" | ||||||||||||||

80 | DN80, 3" | ||||||||||||||

Process connection type | BA1 | ASME flange class 150, suitable for ASME B16.5, raised face (RF) | |||||||||||||

BA2 | ASME flange class 300, suitable for ASME B16.5, raised face (RF) | ||||||||||||||

BA4 | ASME flange class 600, suitable for ASME B16.5, raised face (RF) | ||||||||||||||

CA4 | ASME flange class 600, suitable for ASME B16.5, ring joint (RJ) | ||||||||||||||

BD4 | EN flange PN 40, suitable for EN 1092-1 type B1, raised face (RF) | ||||||||||||||

ED4 | EN flange PN 40, suitable for EN 1092-1 type E, spigot | ||||||||||||||

FD4 | EN flange PN 40, suitable for EN 1092-1 type F, recess | ||||||||||||||

GD4 | EN flange PN 40, suitable for EN 1092-1 type D, groove | ||||||||||||||

BD6 | EN flange PN 100, suitable for EN 1092-1 type B1, raised face (RF) | ||||||||||||||

ED6 | EN flange PN 100, suitable for EN 1092-1 type E, spigot | ||||||||||||||

FD6 | EN flange PN 100, suitable for EN 1092-1 type F, recess | ||||||||||||||

GD6 | EN flange PN 100, suitable for EN 1092-1 type D, groove | ||||||||||||||

BJ1 | JIS flange 10K, JIS B 2220 | ||||||||||||||

BJ2 | JIS flange 20K, JIS B 2220 | ||||||||||||||

BP1 | JPI flange class 150 | ||||||||||||||

BP2 | JPI flange class 300 | ||||||||||||||

BP4 | JPI flange class 600 | ||||||||||||||

TG9 | Process connection with internal thread G | ||||||||||||||

TT9 | Process connection with internal thread NPT | ||||||||||||||

HS4 | Clamp process connection according to DIN 32676 series A | ||||||||||||||

HS8 | Clamp process connection according to DIN 32676 series C (Tri-Clamp) | ||||||||||||||

HS9 | Clamp process connection according to JIS/ISO 2852 | ||||||||||||||

Sensor housing 0material | 0 | Stainless steel 1.4301/304, 1.4404/316L | |||||||||||||

1 | Stainless steel 1.4404/316L | ||||||||||||||

Process fluid temperature range | 0 | Standard integrate: -50 to 150℃ (-58 to 302℉), remote type: -70 to 200 °C (-94 – 392 °F) | |||||||||||||

2 | Mid-range: -70 to 230℃ (-94 to 446℉) | ||||||||||||||

3 | High: 0 to 350℃ (32 to 662℉) | ||||||||||||||

Mass flow and density accuracy | E7 | Liquid: 0.2 % maximum mass flow deviation, 4 g/l density deviation | |||||||||||||

D7 | Liquid: 0.15 % maximum mass flow deviation, 4 g/l density deviation | ||||||||||||||

C6 | Liquid: 0.1 % maximum mass flow deviation, 3 g/l density deviation | ||||||||||||||

C3 | Liquid: 0.1 % maximum mass flow deviation, 1 g/l density deviation | ||||||||||||||

C2 | Liquid: 0.1 % maximum mass flow deviation, 0.5 g/l density deviation | ||||||||||||||

70 | Gas: 0.75% maximum mass flow deviation | ||||||||||||||

50 | Gas: 0.5% maximum mass flow deviation | ||||||||||||||

Design and housing | 0 | Integral type with "urethane-cured polyester powder coating" coated aluminum transmitter housing | |||||||||||||

2 | Integral type with "corrosion protection coating" coated aluminum transmitter housing | ||||||||||||||

A | Remote type with "urethane-cured polyester powder coating" coated aluminum transmitter housing and standard neck sensor | ||||||||||||||

B | Remote type with "urethane-cured polyester powder coating" coated aluminum transmitter housing and long neck sensor | ||||||||||||||

E | Remote type with "corrosion protection coating" coated aluminum transmitter housing and standard neck sensor | ||||||||||||||

F | Remote type with "corrosion protection coating" coated aluminum transmitter housing and long neck sensor | ||||||||||||||

J | Remote type stainless steel transmitter and standard neck sensor | ||||||||||||||

K | Remote type stainless steel transmitter and long neck sensor | ||||||||||||||

Ex approval | NN00 | None | |||||||||||||

KF21 | ATEX, explosion group IIC and IIIC | ||||||||||||||

KF22 | ATEX, explosion group IIB and IIIC | ||||||||||||||

SF21 | IECEx, explosion group IIC and IIIC | ||||||||||||||

SF22 | IECEx, explosion group IIB and IIIC | ||||||||||||||

GF21 | EAC Ex, explosion group IIC and IIIC | ||||||||||||||

GF22 | EAC Ex, explosion group IIB and IIIC | ||||||||||||||

FF11 | FM, groups A, B, C, D, E, F, G | ||||||||||||||

FF12 | FM, groups C, D, E, F, G | ||||||||||||||

UF21 | INMETRO, explosion group IIC and IIIC | ||||||||||||||

UF22 | INMETRO, explosion group IIB and IIIC | ||||||||||||||

NF21 | NEPSI, explosion group IIC and IIIC | ||||||||||||||

NF22 | NEPSI, explosion group IIB and IIIC | ||||||||||||||

PF21 | Korea Ex, explosion group IIC and IIIC | ||||||||||||||

PF22 | Korea Ex, explosion group IIB and IIIC | ||||||||||||||

Cable entries | 2 | ANSI ½" NPT | |||||||||||||

4 | ISO M20x1.5 | ||||||||||||||

Communication type and I/O | JA | active current output HART,1 passive pulse or status output | |||||||||||||

JB | 2 active current outputs one with HART,2 passive pulse or status outputs | ||||||||||||||

JC | 2 active current outputs one with HART,1 passive pulse or status output,1 voltage-free status input | ||||||||||||||

JD | 1 active current output HART,2 passive pulse or status outputs,1 passive status output | ||||||||||||||

JE | 1 active current output HART,2 passive pulse or status outputs,1 voltage-free status input | ||||||||||||||

JF | 1 active current output HART,1 passive pulse or status output,1 active pulse or status output with pull-up resistor,1 voltage-free status input | ||||||||||||||

JG | 1 active current output HART,1 passive pulse or status output,1 active pulse or status output,1 voltage-free status input | ||||||||||||||

JH | 1 active current output HART,1 passive pulse or status output,1 passive current output,1 active current input | ||||||||||||||

JJ | 1 active current output HART,2 passive pulse or status outputs,1 active current input | ||||||||||||||

JK | 1 active current output HART,1 passive pulse or status output,1 voltage-free status input,1 active current input | ||||||||||||||

JL | 1 active current output HART,1 passive pulse or status output,1 passive current output,1 passive current input | ||||||||||||||

JM | 1 active current output HART, 2 passive pulse or status outputs,1 passive current input | ||||||||||||||

JN | 1 active current output HART,1 passive pulse or status output,1 voltage-free status input,1 passive current input | ||||||||||||||

JP | 2 passive current outputs one with HART,1 passive pulse or status output | ||||||||||||||

JQ | 2 passive current outputs one with HART,2 passive pulse or status outputs | ||||||||||||||

JR | 2 passive current outputs one with HART,1 passive NAMUR pulse or status output | ||||||||||||||

JS | 2 passive current outputs one with HART,2 passive NAMUR pulse or status outputs | ||||||||||||||

M0 | Modbus output,1 passive pulse or status output | ||||||||||||||

M2 | Modbus output,1 passive pulse or status output,1 active current input | ||||||||||||||

M3 | Modbus output, 2 passive pulse or status outputs | ||||||||||||||

M4 | Modbus output,1 passive pulse or status output, 1 active pulse or status output | ||||||||||||||

M5 | Modbus output, 1 passive pulse or status output, 1 active pulse or status output with pull-up resistor | ||||||||||||||

M6 | Modbus output,1 passive pulse or status output, 1 active current output | ||||||||||||||

M7 | Modbus output, 1 passive pulse or status output, 1 passive current input | ||||||||||||||

Display | 0 | No display | |||||||||||||

1 | With display | ||||||||||||||

Optional codes | /Optional codes | ||||||||||||||

8. Model selection of Supreme 39

Main Code | Suffix Codes | Description | |||||||||||||

RC | Always RC | ||||||||||||||

Transmitter | E | Essential (base function) | |||||||||||||

U | Ultimate (high function) | ||||||||||||||

Sensor | S | Supreme | |||||||||||||

Meter size | 39 | Nominal mass flow : 32 t/h (1200 lb/min), Maximum mass flow: 50 t/h (1800 lb/min) | |||||||||||||

Material of wetted parts | S | Stainless steel 1.4404/316L | |||||||||||||

H | Ni alloy C-22/2.4602 | ||||||||||||||

Process connection size | 80 | DN80, 3" | |||||||||||||

1H | DN100, 4" | ||||||||||||||

1Q | DN125, 5" | ||||||||||||||

Process connection type | BA1 | ASME flange class 150, suitable for ASME B16.5, raised face (RF) | |||||||||||||

BA2 | ASME flange class 300, suitable for ASME B16.5, raised face (RF) | ||||||||||||||

BA4 | ASME flange class 600, suitable for ASME B16.5, raised face (RF) | ||||||||||||||

CA4 | ASME flange class 600, suitable for ASME B16.5, ring joint (RJ) | ||||||||||||||

BD4 | EN flange PN 40, suitable for EN 1092-1 type B1, raised face (RF) | ||||||||||||||

ED4 | EN flange PN 40, suitable for EN 1092-1 type E, spigot | ||||||||||||||

FD4 | EN flange PN 40, suitable for EN 1092-1 type F, recess | ||||||||||||||

GD4 | EN flange PN 40, suitable for EN 1092-1 type D, groove | ||||||||||||||

BD6 | EN flange PN 100, suitable for EN 1092-1 type B1, raised face (RF) | ||||||||||||||

ED6 | EN flange PN 100, suitable for EN 1092-1 type E, spigot | ||||||||||||||

FD6 | EN flange PN 100, suitable for EN 1092-1 type F, recess | ||||||||||||||

GD6 | EN flange PN 100, suitable for EN 1092-1 type D, groove | ||||||||||||||

BJ1 | JIS flange 10K, JIS B 2220 | ||||||||||||||

BJ2 | JIS flange 20K, JIS B 2220 | ||||||||||||||

BP1 | JPI flange class 150 | ||||||||||||||

BP2 | JPI flange class 300 | ||||||||||||||

BP4 | JPI flange class 600 | ||||||||||||||

TG9 | Process connection with internal thread G | ||||||||||||||

TT9 | Process connection with internal thread NPT | ||||||||||||||

HS4 | Clamp process connection according to DIN 32676 series A | ||||||||||||||

HS8 | Clamp process connection according to DIN 32676 series C (Tri-Clamp) | ||||||||||||||

HS9 | Clamp process connection according to JIS/ISO 2852 | ||||||||||||||

Sensor housing 0material | 0 | Stainless steel 1.4301/304, 1.4404/316L | |||||||||||||

1 | Stainless steel 1.4404/316L | ||||||||||||||

Process fluid temperature range | 0 | Standard integrate: -50 to 150℃ (-58 to 302℉), remote type: -70 to 200 °C (-94 – 392 °F) | |||||||||||||

2 | Mid-range: -70 to 230℃ (-94 to 446℉) | ||||||||||||||

3 | High: 0 to 350℃ (32 to 662℉) | ||||||||||||||

Mass flow and density accuracy | E7 | Liquid: 0.2 % maximum mass flow deviation, 4 g/l density deviation | |||||||||||||

D7 | Liquid: 0.15 % maximum mass flow deviation, 4 g/l density deviation | ||||||||||||||

C6 | Liquid: 0.1 % maximum mass flow deviation, 3 g/l density deviation | ||||||||||||||

C3 | Liquid: 0.1 % maximum mass flow deviation, 1 g/l density deviation | ||||||||||||||

C2 | Liquid: 0.1 % maximum mass flow deviation, 0.5 g/l density deviation | ||||||||||||||

70 | Gas: 0.75% maximum mass flow deviation | ||||||||||||||

50 | Gas: 0.5% maximum mass flow deviation | ||||||||||||||

Design and housing | 0 | Integral type with "urethane-cured polyester powder coating" coated aluminum transmitter housing | |||||||||||||

2 | Integral type with "corrosion protection coating" coated aluminum transmitter housing | ||||||||||||||

A | Remote type with "urethane-cured polyester powder coating" coated aluminum transmitter housing and standard neck sensor | ||||||||||||||

B | Remote type with "urethane-cured polyester powder coating" coated aluminum transmitter housing and long neck sensor | ||||||||||||||

E | Remote type with "corrosion protection coating" coated aluminum transmitter housing and standard neck sensor | ||||||||||||||

F | Remote type with "corrosion protection coating" coated aluminum transmitter housing and long neck sensor | ||||||||||||||

J | Remote type stainless steel transmitter and standard neck sensor | ||||||||||||||

K | Remote type stainless steel transmitter and long neck sensor | ||||||||||||||

Ex approval | NN00 | None | |||||||||||||

KF21 | ATEX, explosion group IIC and IIIC | ||||||||||||||

KF22 | ATEX, explosion group IIB and IIIC | ||||||||||||||

SF21 | IECEx, explosion group IIC and IIIC | ||||||||||||||

SF22 | IECEx, explosion group IIB and IIIC | ||||||||||||||

GF21 | EAC Ex, explosion group IIC and IIIC | ||||||||||||||

GF22 | EAC Ex, explosion group IIB and IIIC | ||||||||||||||

FF11 | FM, groups A, B, C, D, E, F, G | ||||||||||||||

FF12 | FM, groups C, D, E, F, G | ||||||||||||||

UF21 | INMETRO, explosion group IIC and IIIC | ||||||||||||||

UF22 | INMETRO, explosion group IIB and IIIC | ||||||||||||||

NF21 | NEPSI, explosion group IIC and IIIC | ||||||||||||||

NF22 | NEPSI, explosion group IIB and IIIC | ||||||||||||||

PF21 | Korea Ex, explosion group IIC and IIIC | ||||||||||||||

PF22 | Korea Ex, explosion group IIB and IIIC | ||||||||||||||

Cable entries | 2 | ANSI ½" NPT | |||||||||||||

4 | ISO M20x1.5 | ||||||||||||||

Communication type and I/O | JA | active current output HART,1 passive pulse or status output | |||||||||||||

JB | 2 active current outputs one with HART,2 passive pulse or status outputs | ||||||||||||||

JC | 2 active current outputs one with HART,1 passive pulse or status output,1 voltage-free status input | ||||||||||||||

JD | 1 active current output HART,2 passive pulse or status outputs,1 passive status output | ||||||||||||||

JE | 1 active current output HART,2 passive pulse or status outputs,1 voltage-free status input | ||||||||||||||

JF | 1 active current output HART,1 passive pulse or status output,1 active pulse or status output with pull-up resistor,1 voltage-free status input | ||||||||||||||

JG | 1 active current output HART,1 passive pulse or status output,1 active pulse or status output,1 voltage-free status input | ||||||||||||||

JH | 1 active current output HART,1 passive pulse or status output,1 passive current output,1 active current input | ||||||||||||||

JJ | 1 active current output HART,2 passive pulse or status outputs,1 active current input | ||||||||||||||

JK | 1 active current output HART,1 passive pulse or status output,1 voltage-free status input,1 active current input | ||||||||||||||

JL | 1 active current output HART,1 passive pulse or status output,1 passive current output,1 passive current input | ||||||||||||||

JM | 1 active current output HART, 2 passive pulse or status outputs,1 passive current input | ||||||||||||||

JN | 1 active current output HART,1 passive pulse or status output,1 voltage-free status input,1 passive current input | ||||||||||||||

JP | 2 passive current outputs one with HART,1 passive pulse or status output | ||||||||||||||

JQ | 2 passive current outputs one with HART,2 passive pulse or status outputs | ||||||||||||||

JR | 2 passive current outputs one with HART,1 passive NAMUR pulse or status output | ||||||||||||||

JS | 2 passive current outputs one with HART,2 passive NAMUR pulse or status outputs | ||||||||||||||

M0 | Modbus output,1 passive pulse or status output | ||||||||||||||

M2 | Modbus output,1 passive pulse or status output,1 active current input | ||||||||||||||

M3 | Modbus output, 2 passive pulse or status outputs | ||||||||||||||

M4 | Modbus output,1 passive pulse or status output, 1 active pulse or status output | ||||||||||||||

M5 | Modbus output, 1 passive pulse or status output, 1 active pulse or status output with pull-up resistor | ||||||||||||||

M6 | Modbus output,1 passive pulse or status output, 1 active current output | ||||||||||||||

M7 | Modbus output, 1 passive pulse or status output, 1 passive current input | ||||||||||||||

Display | 0 | No display | |||||||||||||

1 | With display | ||||||||||||||

Optional codes | /Optional codes | ||||||||||||||

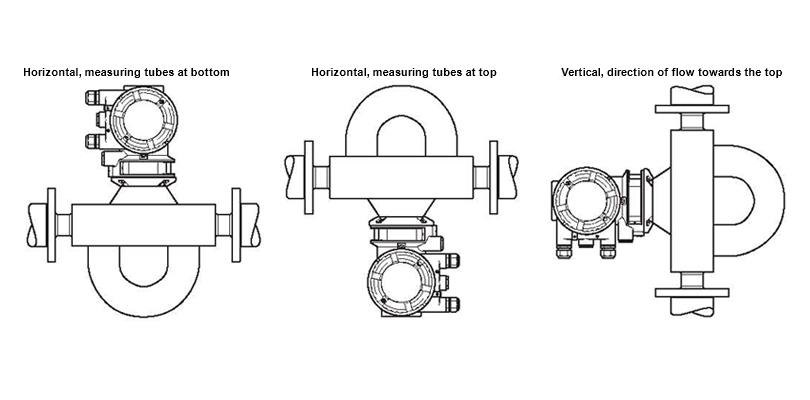

9. Location and position of installation